MicroMed

MicroMed

Excellent

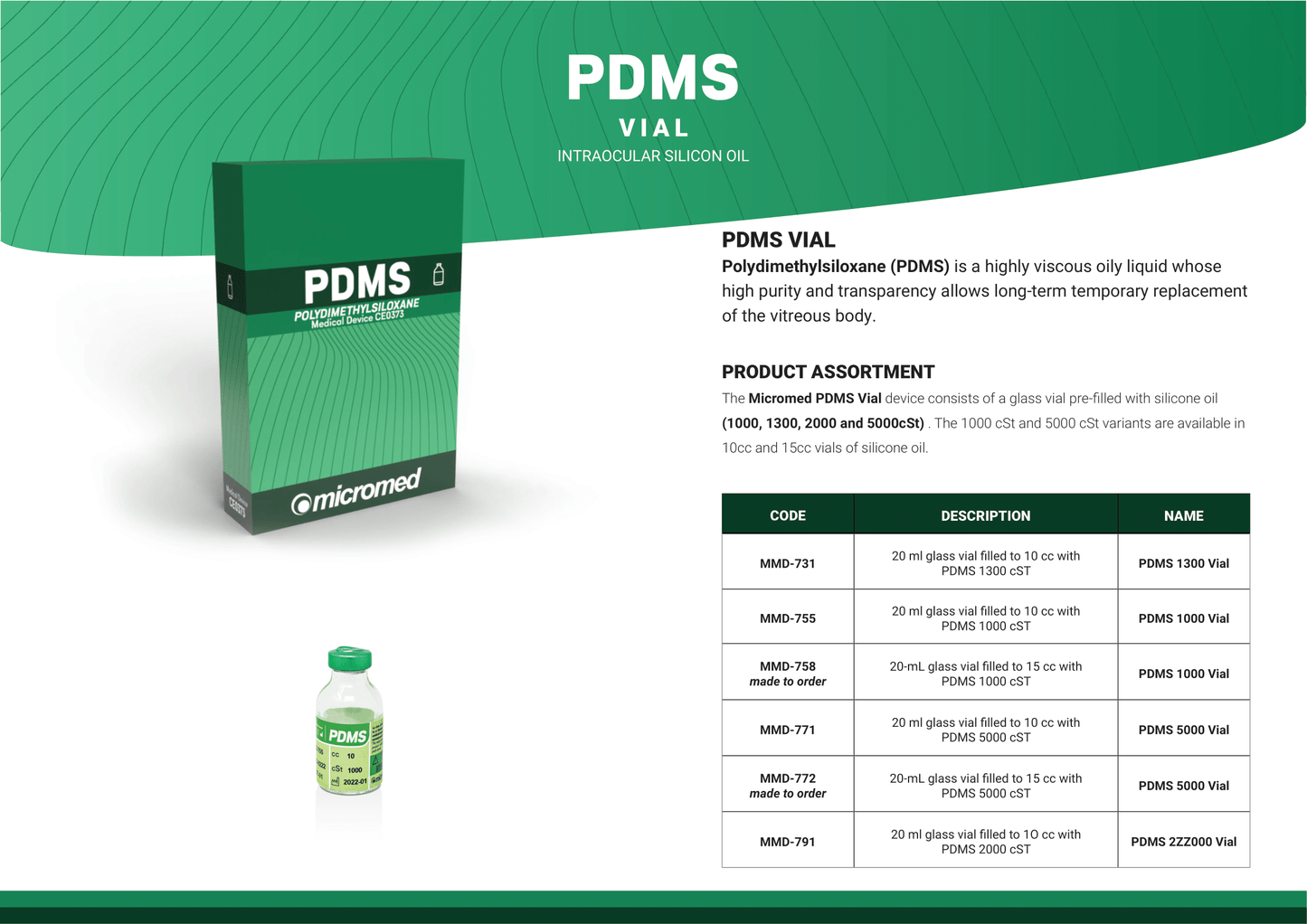

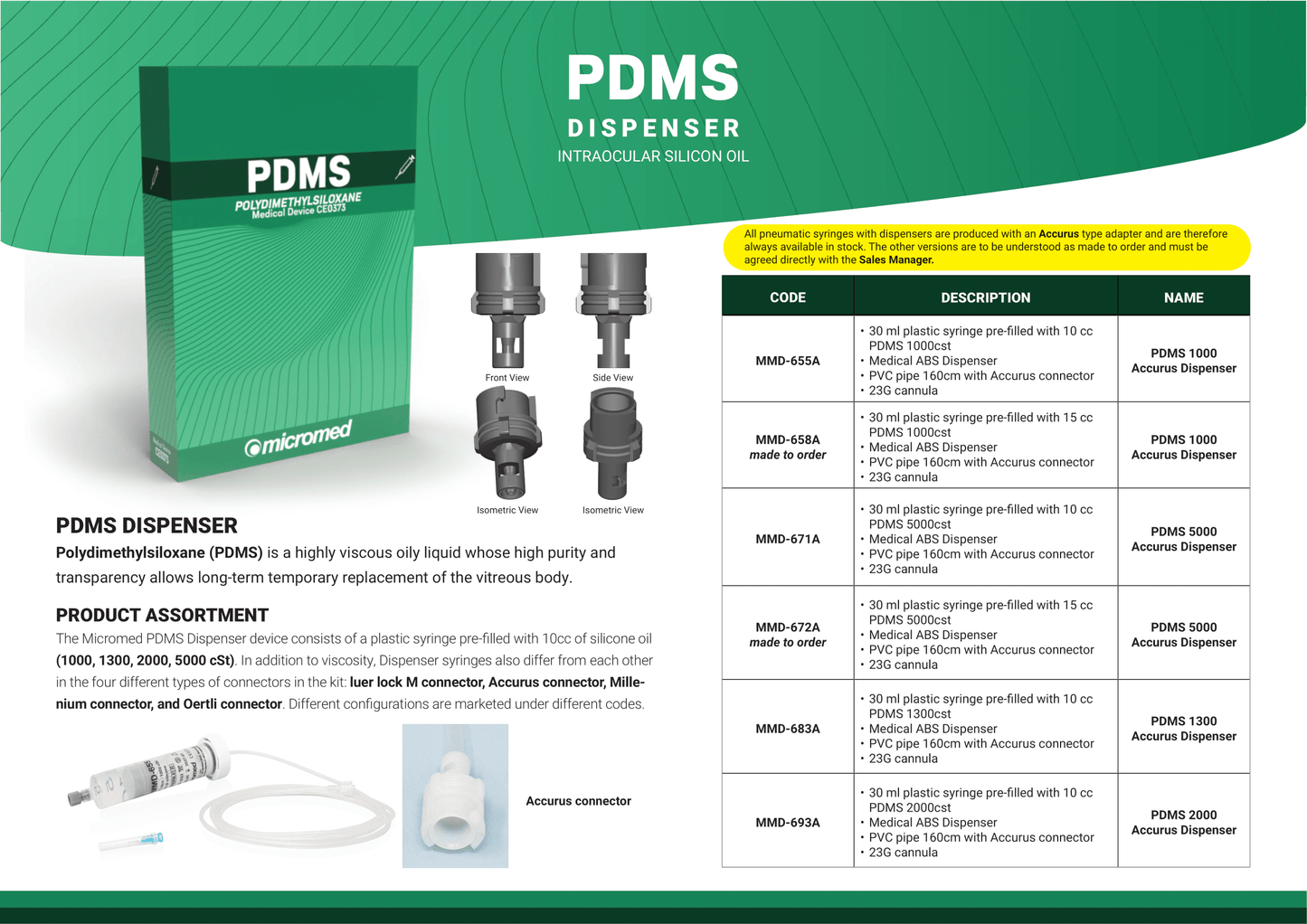

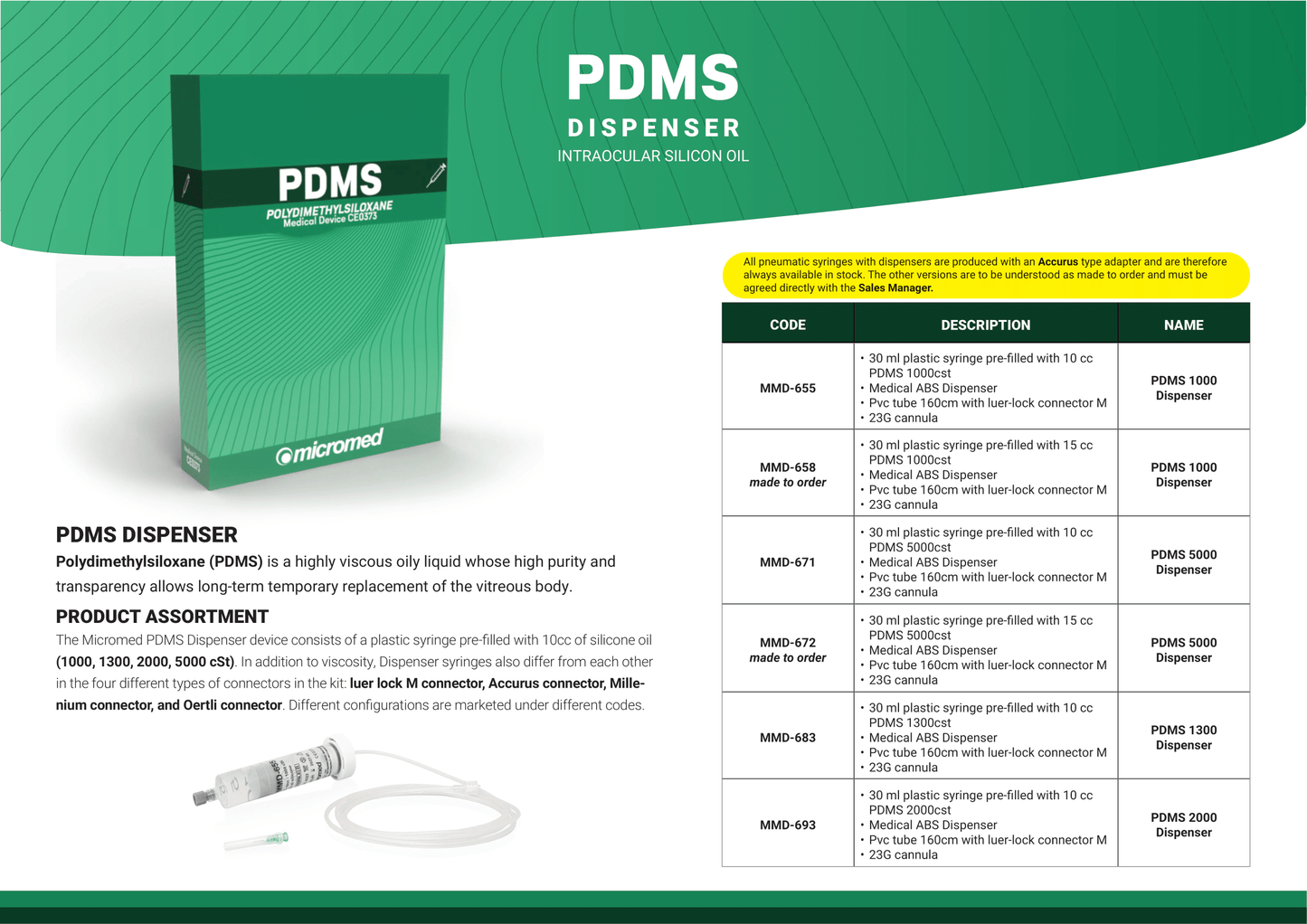

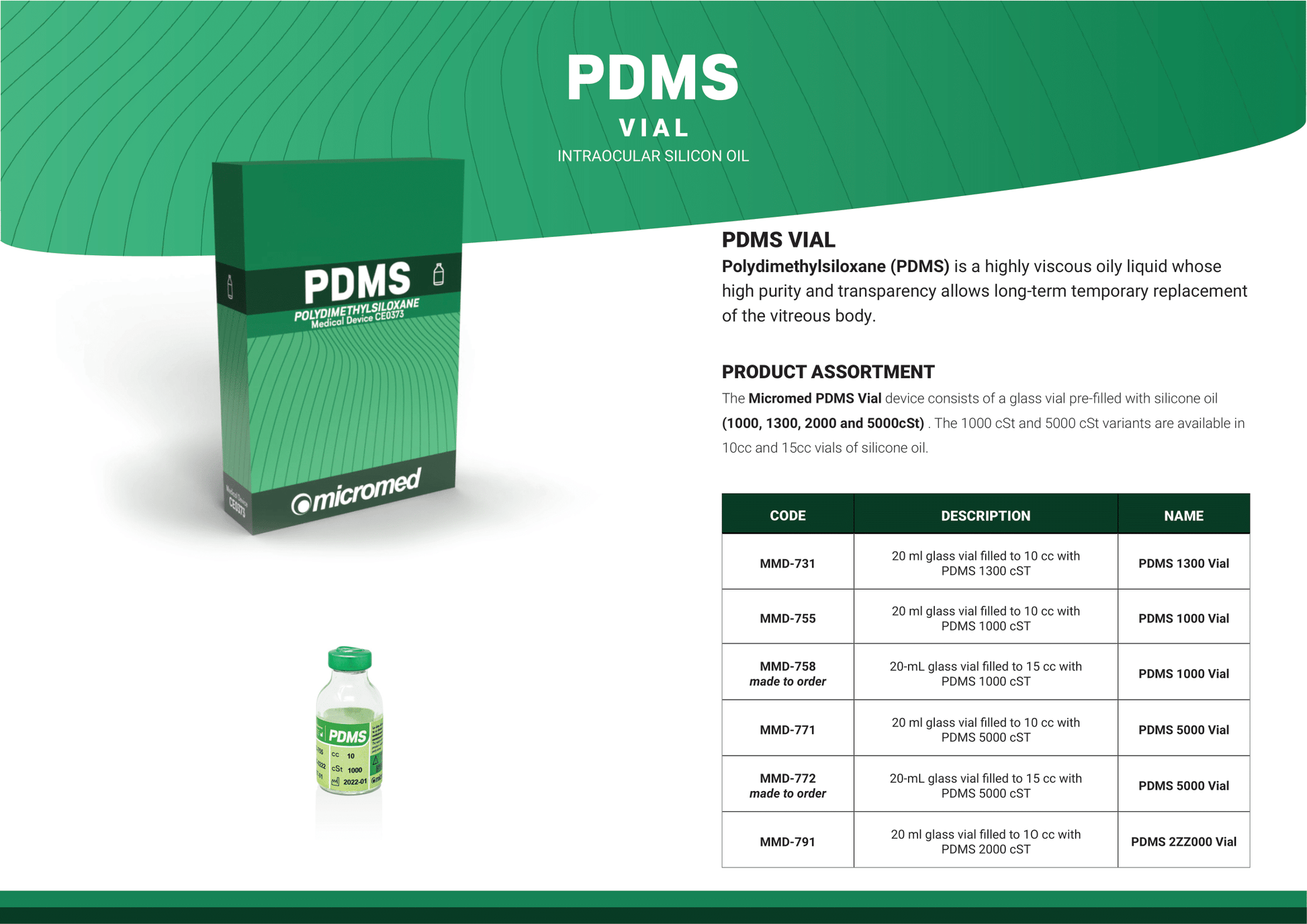

PDMS is used for long-term (at least 30 days) ocular tamponade after vitrectomy surgery.

PDMS undergoes scrupulous biocompatibility testing before packaging, and the chemical

analysis performed allows us to guarantee high purity of the silicone oil due to the presence of

a very low percentage of volatile chains (0.1%).

This product line was approved for marketing in 1999 and is a Class IIB medical device.

Silicones have been used in the medical field for about fifty years. No other material is suffi-

ciently biocompatible, reliable, flexible and easily sterilized as silicone.

Liquid PDMS is indicated and recommended in all world pharmacopoeias for use as a medical

device. It is odorless, tasteless, does not support bacterial growth and does not react with

other materials, but most importantly, it has high compatibility with human tissues and body

fluids.

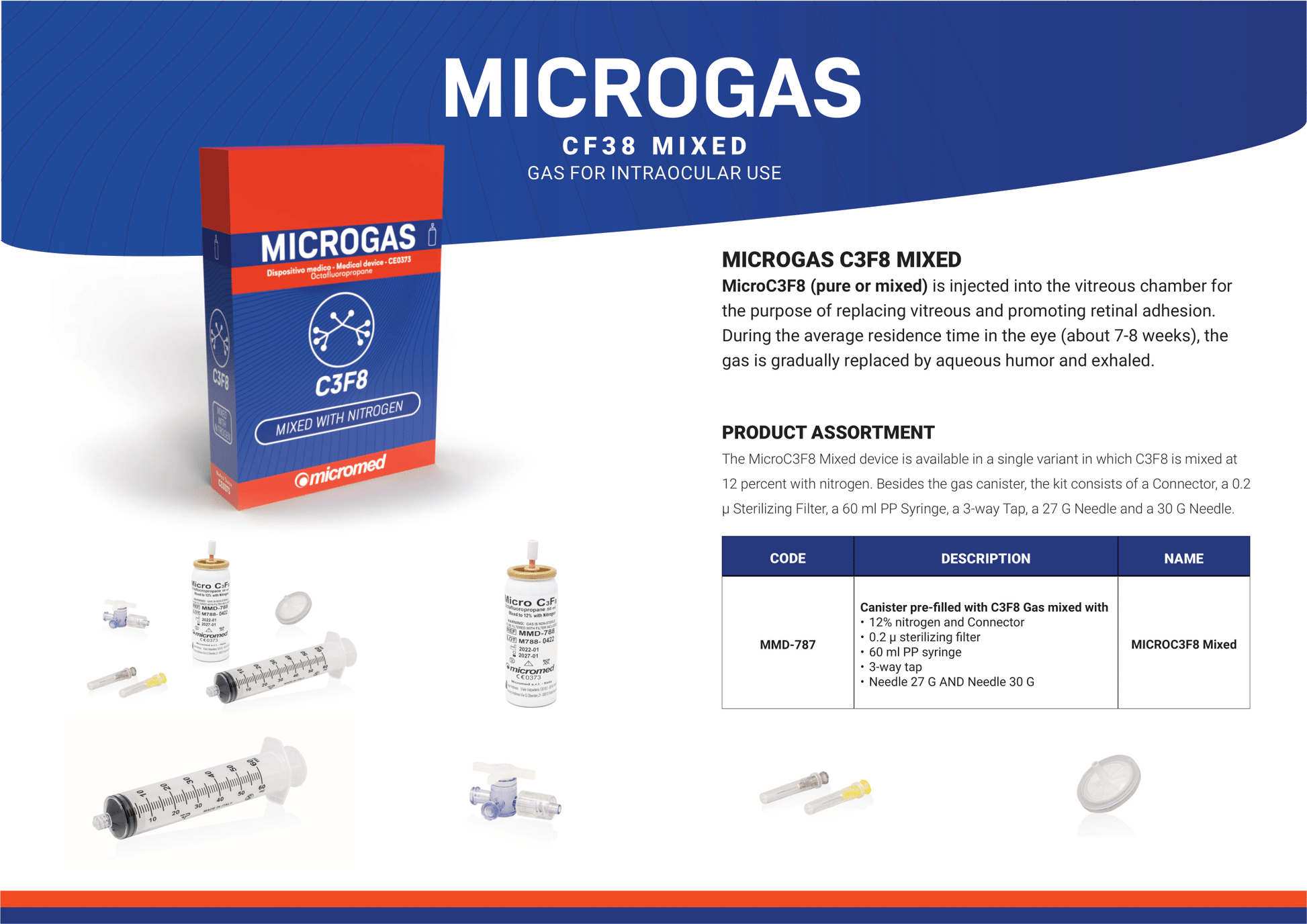

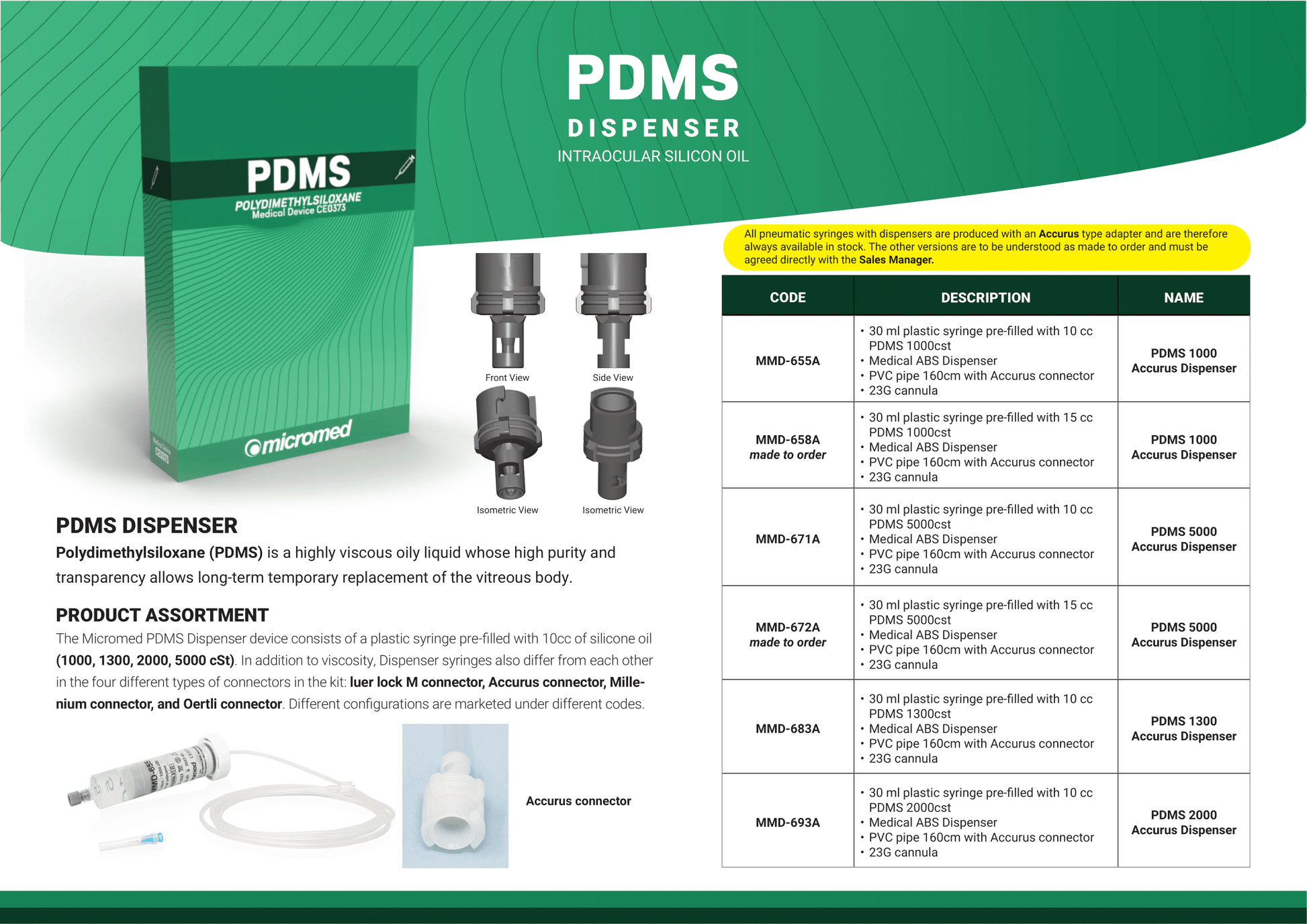

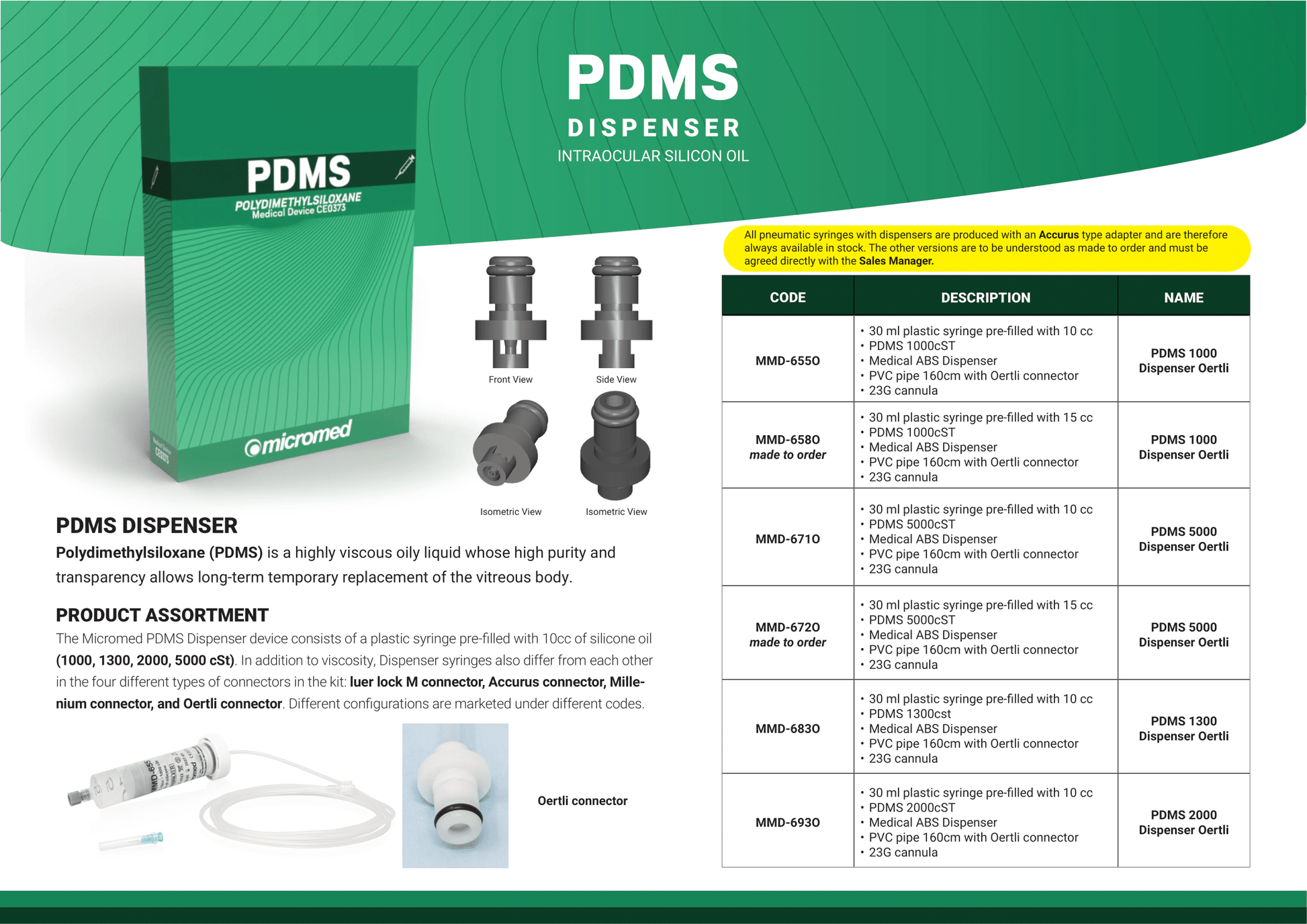

Several product categories belong to the PDMS family, which differ from each other based on

the primary packaging and viscosity of the silicone oil mixture.

Micromed PDMS is marketed in different viscosity variants:

PDMS 1000 characterized by the presence of chain lengths with a standard deviation less

than 0.02% and a typical viscosity of 1000 centiStokes; its braking index is conventionally set

at 1.

The PDMS 1300 centiStokes with the same characteristics but with a 4% higher braking

index.

PDMS 2000 has a braking index greater than 15 percent and is indicated in cases where

emulsification with protein fluids in the eye is likely to occur independent of surgery.

The latest variant is the PDMS 5000 which has a braking index greater than 70 percent and

is indicated in cases where retinal manipulation has been significant, such as in the case of

strong overhanging treatments on major cerclages and for more than 40 percent of the retinal

surface, or in the case of major retinotomies in the presence of cerclage or large retractions

Couldn't load pickup availability

- Easy Setup

- 24/7 VIP Support